I-PP PS PET PE EVA EVOH Umugqa wokukhipha amashidi wezingqimba eziningi zezendlalelo

Izinhlelo zokusebenza eziyinhloko zamaphepha anjalo

Afakwe nokusebenza okuhle kakhulu kwesithiyo, ukusebenza kwe-anti-oxygen kanye ne-anti-humidity, amashidi asetshenziselwa kakhulu ukupakisha i-Jelly, ukupakisha iyogathi, ukupakisha inyama, ukupakisha ukudla okulula, ukupakisha ukudla kwezinga eliphezulu, ukupakisha irayisi lokudla okusheshayo kanye nokupakishwa kwemithi. , ukupakisha izimonyo njll.

Izinzuzo zalo mugqa

I-1) Uhlelo lwe-Gravimetric dosing lokuphatha impahla eluhlaza luyatholakala, olungaqaphela ukuxubana okunembe ngokulinganayo kwezinhlobo ezimbalwa zezingxenye zempahla yokusetshenziswa.

2) Isikulufa esithuthukisiwe kanye nesakhiwo sesakhiwo somgqomo singabona i-plasticization yempahla eluhlaza kanye nokucindezela okuzinzile kanye ne-extrusion ethembekile.

3) Isiguquli sesikrini se-Hydraulic singavimba ngempumelelo ukungcola okuvela ezintweni ezingavuthiwe.

4) Iphampu yegiya ye-Melt engenisiwe ifakwe ukuqinisekisa ingcindezi yezinto ezingavuthiwe ezinzile.

5) I-T die kanye nesithwebuli sokujiya esiku-inthanethi sihlonyiselwe ndawonye ukuze kuqinisekiswe ukushuba kweshidi kumfaniswano kakhudlwana.

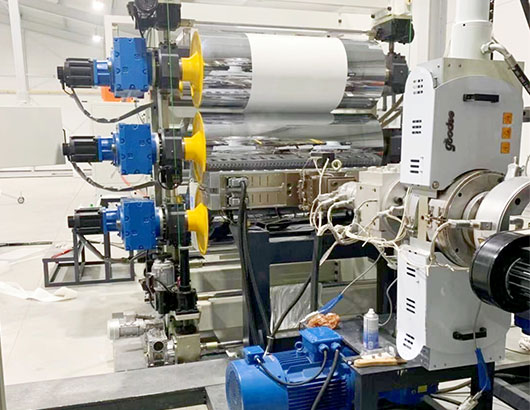

6) Amakhalenda ama-roller amathathu angasebenzisa uhlobo oluvundlile, uhlobo olutshekile, uhlobo olume mpo noma eminye imiklamo yohlobo lwama-engeli ukuhlangabezana nezinhlobo ezahlukene zamashidi extrusion.Uhlelo lokushayela lwamakhalenda ama-roller lungaba ukulawulwa kwezimoto ezincishisiwe noma ukulawulwa kwama-servo motors.

7) I-online side trim granulator kanye nesistimu yokudlulisa ipayipi ingadlulisela imiphetho eseceleni ku-extruder yangaphambili ngokuzenzakalelayo.

I-8) Iyunithi yokugcoba uwoyela we-Silicone ingaqinisekisa ukuthi amashidi asuswa kalula ekubunjweni kwe-thermoformed.

9) Idizayini ye-accumulator yamaSpredishithi yejubane eliphezulu lomugqa

10) Izingxenye zomhlangano ezidumile emhlabeni wonke, njenge-SHINI, MOTAN, JC TIMES, NORDSON EDI, SCANTECH, NORD, MAAG, GEFRON, NSK, ABB, SIEMENS njll.

7)Ubuchwepheshe bokonga amandla obusebenzayo obunokusetshenziswa kwamandla okuphansi kakhulu.

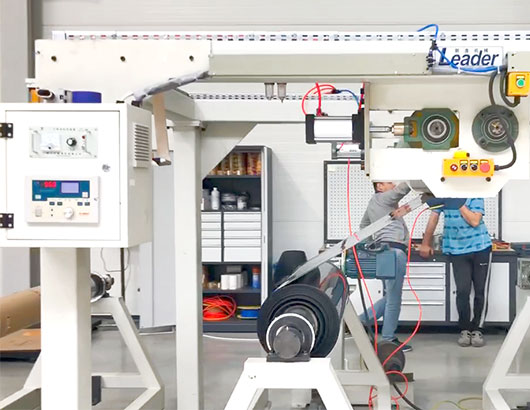

Ulayini wonke usebenzisa isilawuli sesikrini sokuthinta esizenzakalelayo se-Siemens PLC;i-electron

Idatha enkulu yezobuchwepheshe

| Mimodeli ye-extruder | I-LSJ-105 | I-LSJ-120 | I-LSJ-150 |

| Cimodeli ye-o-extruder | LSJ-30, LSJ-45, LSJ-65 | ||

| Simpahla ewusizo | I-PP PE PET PS | I-PP PE PET PS | I-PP PE PET PS |

| Pububanzi bomzila | 600-800 mm | 800-1000mm | 1000-1200mm |

| Ukujiya komkhiqizo | 0.15-2mm | 0.15-2mm | 0.15-2mm |

| Isakhiwo somkhiqizo | MI-ono layer, i-co-extrusion enezingqimba eziningi, | ||

| Mumthamo wezembe | 200-300kg/h | 400-550kg/h | 600-1000kg/h |